Quality Taiwanese lathes with excellent safety and reliability

High-quality, Taiwanese-built Gosan lathes are an excellent choice for metalworking professionals – with a wide range to meet individual requirements. They feature advanced safety features such as interlock chuck guards and electromagnetic braking – as well as excellent thread cutting capabilities.

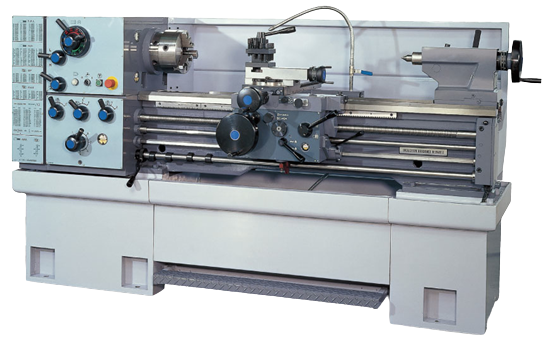

PRECISION ENGINE LATHE (Spindle bore 58mm. 2-1/4inch)

FEATURES

- Heavy duty geared head; hardened and ground gears.

- 58mm hole through spindle.

- 3-point supported spindle using 2 precision taper roller bearings and 1 ball bearing.

- 12 steps spindle speeds 20 – 2000 rpm. shift in geometric progression.

- Forced spray lubrication system used for headstock.

- Quick-change universal gearbox for inch, metric, DP, MP, threading, and multiple thread.

- One shot lubrication pump supply oil cross slide and bed-ways.

- Adjustable overload clutch in apron to ensure proper cutting load.

- Cross slide screw permanently immersed in oil and supported by thrust bearing.

- Electro-magnetic brake

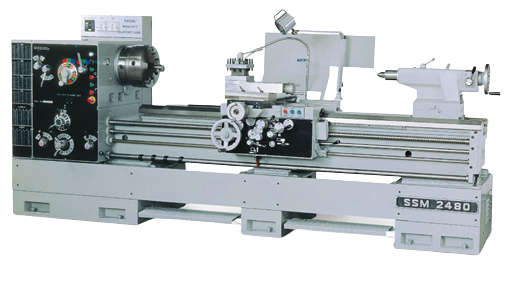

PRECISION ENGINE LATHE (Spindle bore 86mm. 3-3/8inch)

FEATURES

- Heavy duty geared head; hardened and ground gears.

- 86mm. 3-3/8inch hole through spindle.

- 3-point supported spindle using 2 precision taper roller bearings and 1 ball bearing.

- 12 steps spindle speeds 20 – 1800 rpm. shift in geometric progression.

- Quick-change universal gearbox for inch, metric, DP, MP, threading, and multiple thread.

- Forced spray lubrication system used for headstock.

- One shot lubrication pump supply oil cross slide and bed-ways.

- Adjustable overload clutch in apron to ensure proper cutting load.

- Cross slide screw permanently immersed in oil and supported by thrust bearing.

- Induction hardened and precision ground bed-way.

- One-piece base for maximum rigidity.

HEAVY DUTY LATHE (15HP Main motor; spindle bore 105mm 4-1/8inch)

FEATURES

- 4-1/8in (105mm) Spindle bore; D1-11 camlock spindle nose; 3-bearing spindle support.

- 18 Spindle speeds, 10-1200 rpm, with electro-magnetic brake.

- Electro-magnetic clutch mounted in Headstock, for spindle speed changed without stopping motor.

- Automatic forced lubrication in headstock is moved by a direct motor drive lubrication gear pump, and oil tank is equipped in the leg of machine to minimize the cooling of oil.

- Heavy duty geared head; hardened and ground gears.

- 15HP Main spindle motor.

- Quick-change universal gearbox for inch, metric, DP, MP, threading, and multiple thread, all function without any change gears.

- Four-way rapid carriage movement.

- Automatic lubrication in saddle and apron assembly.

- Adjustable overload clutch in apron to ensure proper cutting load.

- 2 speeds tailstock barrel.

- 19in. (485mm) wide bed ways, induction hardened and ground.

Frequently Asked Questions

Gosan Lathes are high-quality Taiwanese metalworking lathes that boat a wide array of functions allowing any metalworker to get the job done. Gosan Lathes are famous for their advanced safety features, including interlocking chuck guards and electromagnetic braking, ensuring that when you use a Gossan Lathe you are as protected as can be.

Lathes create symmetrical components and objects by rotating a piece of material at high speed while the user holds a cutting tool to it in order to shape an object. Metalworking lathes can be used to create screws, bolts, nuts, or more heavy duty machine components. They can also be used to polish or finish symmetrical metalwork evenly. The basic working principle of lathes is the extreme rotating of the work piece, coupled with the careful application of a cutting tool.

Precision lathes function much in the same way as regular lathes, using the same operational principles but with one distinct difference. Precision lathes are computerised and automatic. Using computer software, a precision lathe is able to be fed a series of instructions that tell the cutting tool (attached to a robotic arm) how, where, when, and what kind of cutting tool to use in order to achieve the desired outcome. Modern Tools provides two Gosan Precision Lathes for sale

There are 8 parts to every Lathe. The Headstock is located on the left and contains gears, spindles, chucks, control levers, and feed controllers. The tailstock is on the right of the lathe, and supports the work. The Bed is where all the parts of the lathe are bolted onto. The Carriage lies between the head and tailstock, and contains the apron, saddle, compound rest, cross slide, and tool post. The Lead Screw moves the carriage during threading. The feed rod moves the carriage left to right and vice versa. The Chip Pan sits at the bottom of the lathe and collects any chipped materials that may break from the work while using the lathe. The final part common to every lathe is the Hand wheel used to operate the cross slide, carriage, tailstock, and more.