SmartVent leads in extraction & filtration of welding Dust, Fume, Oil mist, odour and ambient cooling.

With more than 20 years expert experience in product design and various scales of filed application in metal working/CNC processing, food and Pharmaceutical industry.

Downdraft Tables for Fumes and Smoke

With products available for plasma cutting fumes, welding fumes, soldering fumes, grinding dust and smoke, SmartVent downdraft tables have an efficient way to protect your workers from hazardous fumes, dust and smoke. With more than 20 years expert experience in product design, highly effective filtration and tough build quality SmartVent ensures these downdraft tables won’t let you down.

The SmartVent downdraft table is undoubtedly one of the best downdraft tables for sale in the market. These downdraft tables are made with the sole purpose of filtering out any harmful fuels, making it one of the best downdraft extractors in Australia. If you need a high-quality downdraft extractor that keeps your workers safe during their industrial tasks, then the SmartVent downdraft table is certainly an option for you.

FE-068E-S

- SmartVent Downdraft Tables.

- A Deflector under the table to capture welding sparks.

- Easy access to the Pleated Filter.

- Working Light included.

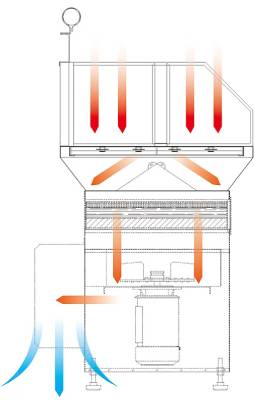

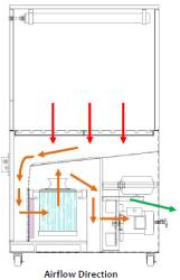

How it works

- STEP 1

Fume extracted via Table Surface Hole Inlet.

- STEP 2

Being downward-drafted into the Deflector for capturing welding sparks.

- STEP 3

Then fume being conducted down to the Filtration Drawer, Stainless Mesh for welding sparks & Pleated Filter for fine dust.

- STEP 4

Clean air being returned to the workplace from the Exhausting Outlet.

2-Stage Filtrations

How it works

- Stage 1

Aluminium Mesh (2) Capturing sparks and steel chips.

- Stage 2

Pleated Cartridge Filter that be can cleaned by pulse-jet cleaning of the cartridge filter from an air compressor.

Specifications

Model No. | FE-068E-S |

Motor | 240 Volt |

Airflow | 756 ft3/min |

1284 m3/hr | |

Filter Media | 3.69 m2 |

Table Size (mm) | 710 x 710 |

Packaging Size (cm) | 101 × 90.5 × 145 |

N.W./G.W. (kg) | 170/210 |

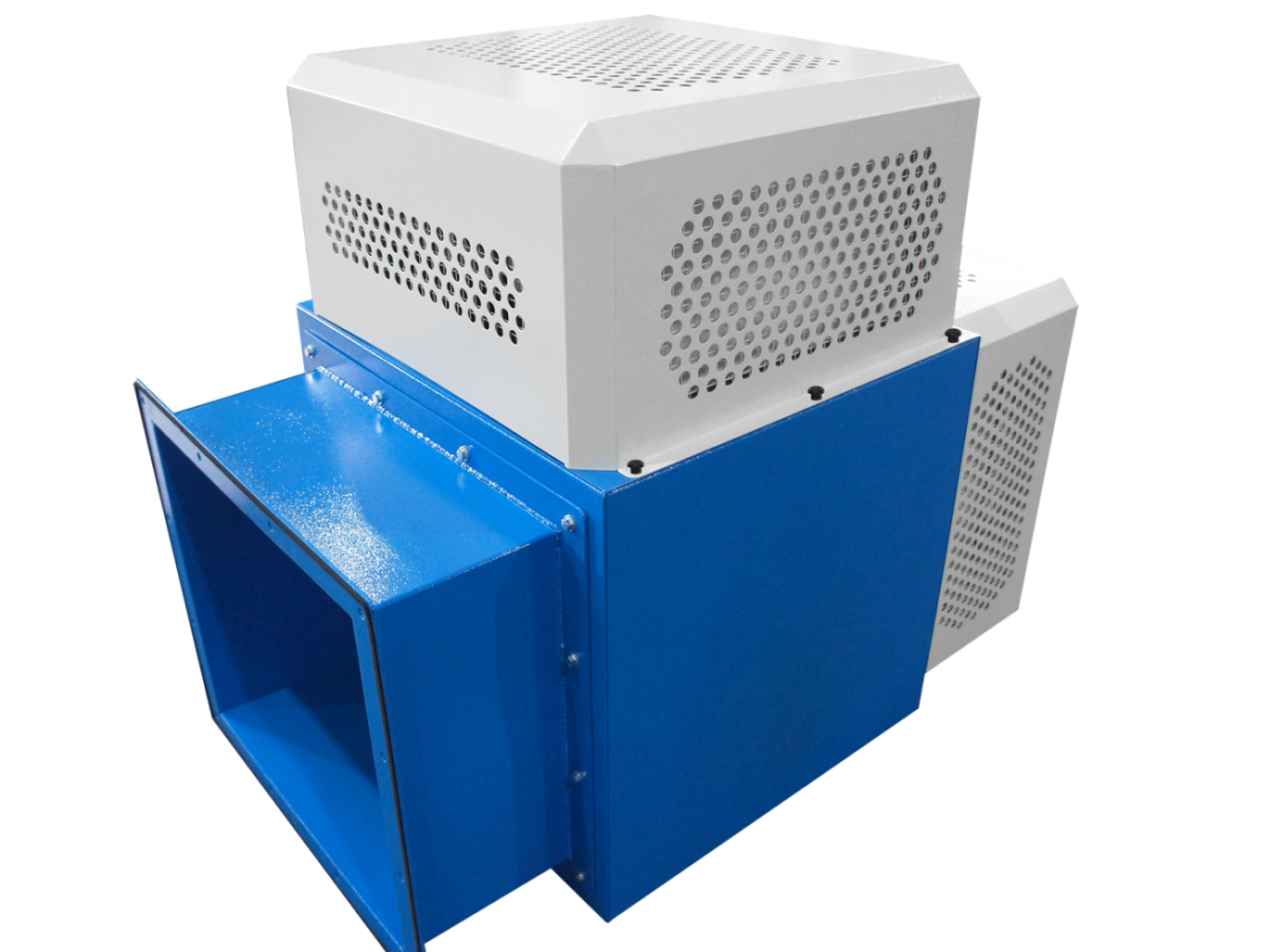

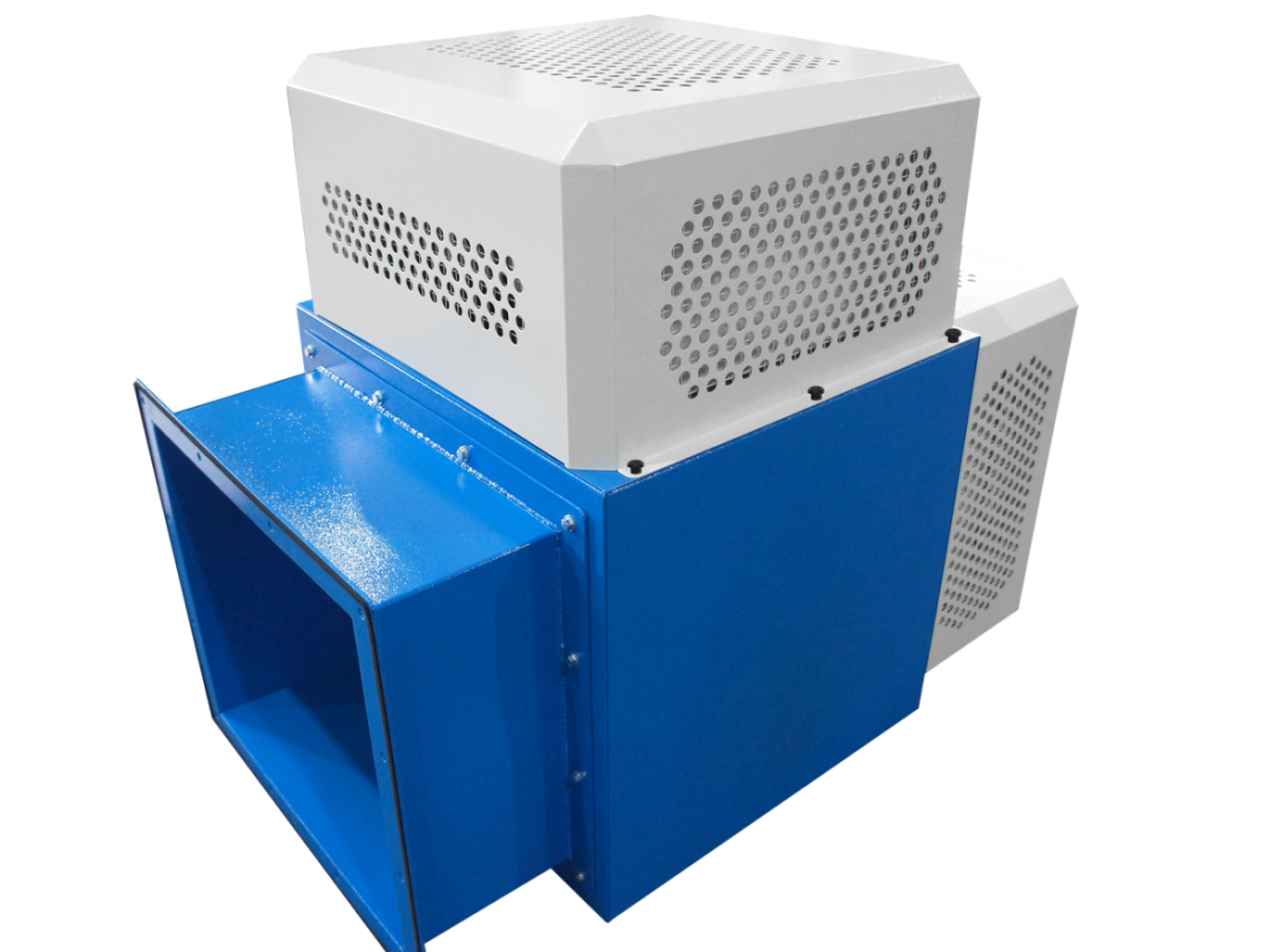

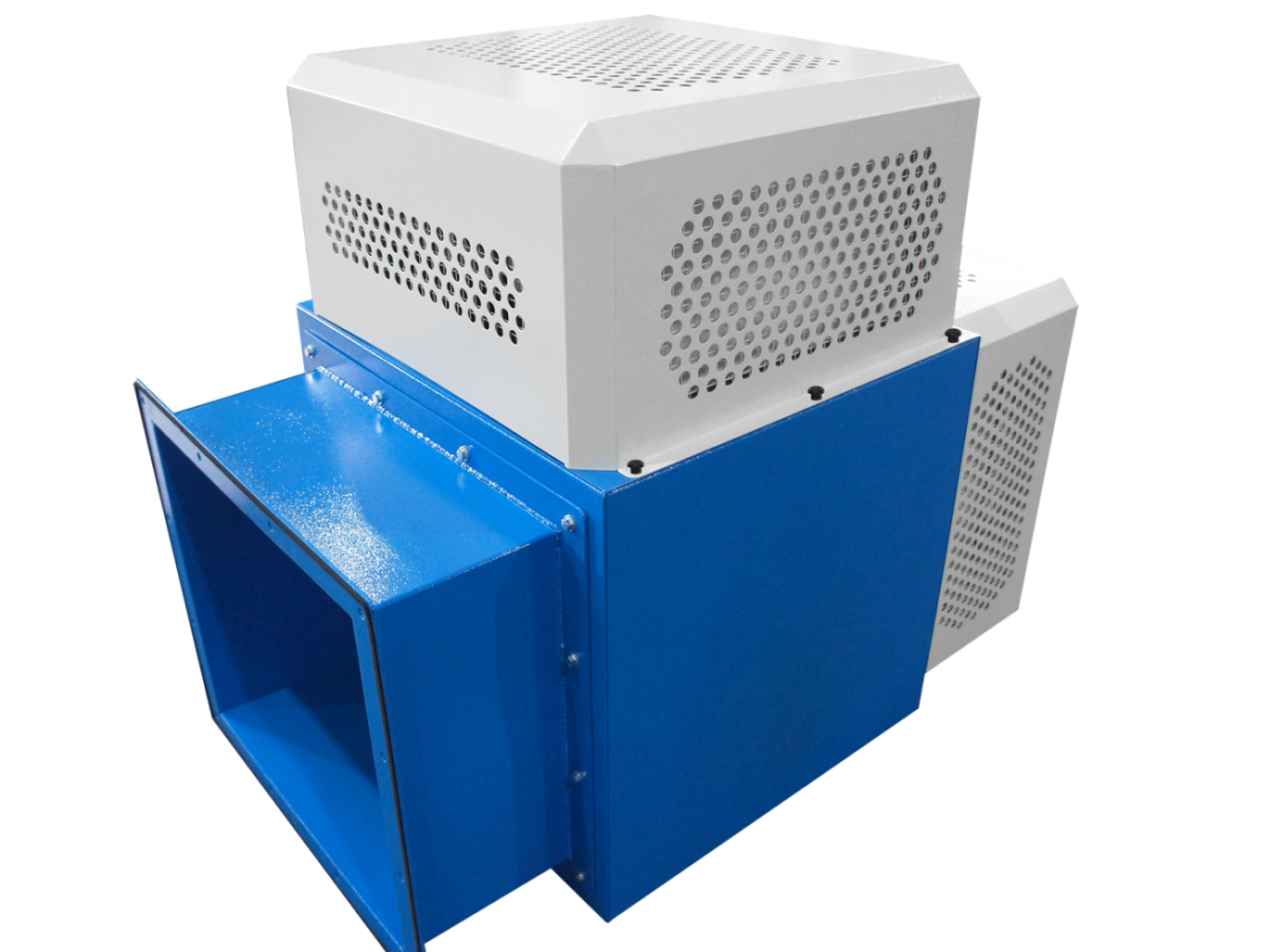

SDT-3 / SDT-5

SmartVent Downdraft Tables

Manual Air Pulse Jet Cartridge Cleaning.

Cartridge: 99% of 1 Micron filter efficiency

Heavy gauge powder coated steel

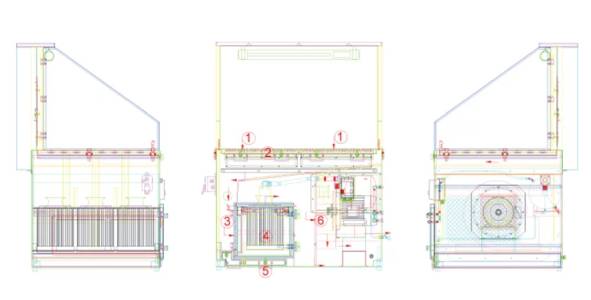

How it works

- STEP 1

Air downward-drafted via Table Surface Hole Inlet 1, drawer 2below for filtering large welding wastes.

- STEP 2

Extracted air being passed through Aluminium Mesh 3 for trapping fire sparks.

- STEP 3

Being conducted into Cartridge Filters 4 for screening fine dusts.

- STEP 4

Larger particles being falling down onto the bottom dust collecting drawer 5

- STEP 5

Clean air exhausted out by Blower 6 via outlet.

3-Stage Filtrations

How it works

- STEP 1

Pre-& after dust drawer Trapping large welding waste to protect the filter media.

- STEP 2

AluminiumMesh (1) Capturing sparks and steel chips.

- STEP 3

Cartridge Filter (3) being coated with TEFLON, featuring 99% of 1-micron filter efficiency.

Optional Accessories

HEPA Module / Castors with locking brake

SDT 3 – $13,950

exc gst

SDT 5 – $15,950

exc gst

HEPA Module – $1950 exc gst

Castors with locking brake – $173 exc gst

Specifications

Model No. | SDT-3 | SDT-5 |

Motor | 3 HP | 5 HP |

Airflow | 1500 ft3/min | 2340 ft3/min |

2547 m3/hr | 3973.32 m3/hr | |

Table Size (mm) | 1240 x 930 | 1240 x 930 |

G.W. (kg) | 615 | 615 |

SDT-7.5

- SmartVent Downdraft Tables.

- Manual Air Pulse Jet Cartridge Cleaning.

- Cartridge: 99% of 1 Micron filter efficiency.

- Heavy gauge powder coated steel.

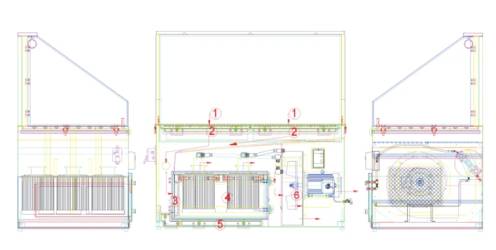

How it works

- STEP 1

Air downward-drafted via Table Surface Hole Inlet 1, drawer 2below for filtering large welding wastes.

- STEP 2

Extracted air being passed through Aluminium Mesh 3 for trapping fire sparks.

- STEP 3

Being conducted into Cartridge Filters 4 for screening fine dusts.

- STEP 4

Larger particles being falling down onto the bottom dust collecting drawer 5

- STEP 5

Clean air exhausted out by Blower 6via outlet.

3-Stage Filtrations

How it works

- STEP 1

Pre-& After Dust Drawer Trapping large welding waste to protect the filter media.

- STEP 2

AluminiumMesh (2) Capturing sparks and steel chips.

- STEP 3

Cartridge Filter (6 Being coated with TEFLON, featuring 99% of 1-micron filter efficiency.

Optional Accessories

HEPA Module / Castors with locking brake

SDT 7.5 – $19,950

exc gst

HEPA Module – $1,950

exc gst

HEPA Module – $1950 exc gst

Castors with locking brake – $173 exc gst

Specifications

Model No. | SDT-7.5 |

Motor | 7.5 HP |

Airflow | 3000 ft3/min |

5094 m3/hr | |

Table Size (mm) | 1670 x 930 |

G.W. (kg) | 618 |

SDT-10

- SmartVent Downdraft Tables

- Welding Fume Collection

- Grinding Dust Collection

- Dry Dust Collection

Product Features:

- 2-Stage Filtrations

- Side Panels: Close for keeping fume &dust inside; Open for big workpiece

- Manual air pulsejet cartridge cleaning

- Fixture Hole Ø 16mm Desktop

Filtration Stage

- Aluminium Mesh

- Cartridge Filter

How does the extraction/filtration work?

1. Air downward-drafted via Table Surface Hole Inlet, drawer below for filtering large welding wastes.

2. Extracted air being passed through Aluminium Mesh for trapping fire sparks.

3. Being conducted into Cartridge Filters for screening fine dusts.

4. Larger particles being falling down onto the bottom dust collecting drawer.

5. Clean air exhausted out by Blower via outlet.

Optional Accessories

SDT 10 – $23,950

exc gst

HEPA Module – $1950 exc gst

Castors with locking brake – $173 exc gst

Custom

Downdraft Table

CUSTOM MADE MODELS AVAILABLE PLEASE CONTACT US WITH YOUR REQUIREMENTS.

Specifications

Model No. | SDT-10 |

Motor | 10 HP |

Airflow | 4000 ft3/min |

6792 m3/hr | |

No. of Cartridges | 9 pcs |

Table Size (mm) | 2350 x 1130 |

N.W./G.W. (kg) | 695/775 |