The Hardest Welding Table - Worldwide

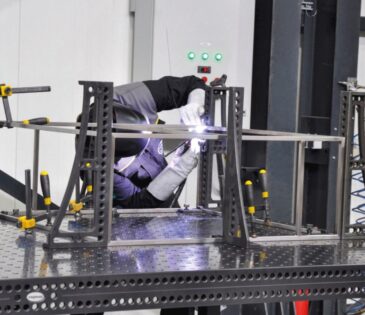

Improve the quality of your work and reduce setup time with Siegmund welding tables and tools. Siegmund has combined the hardness of plasma nitrided steel and high-quality German engineering with a versatile clamping and fixturing tool system to produce the ultimate in welding tables on offer in Australia. Discover the precision and reliability of Siegmund welding tables at Modern Tools, the go-to supplier in Australia.

Welding Bench

Rapid, Highly Accurate Fabrication with Flexible Sizing and Tool-Sets

Siegmund welding tables offer a wide range of sizes and table specifications to suit all applications. Our safe and efficient welding benches optimise your workplace. System 28 tables feature 28mm precision drilled holes, with a grid and drilling distance of 100mm. System 22 tables feature 22mm precision drilled holes, with a grid and drilling distance of 50mm. System 16 tables have smaller 16mm holes, with a reduced grid and drilling distance of 50mm. System 28, System 22 and System 16 are available with a wide range of tools and accessories to fit. If you’re unsure which table is right for you, feel free to contact our expert team to discuss your needs. Modern Tools offers a durable and versatile welding table to enhance your welding projects.

The Toughest Surface – Plasma-Nitrided Tool Steel

Using a plasma-nitriding process perfected over years at their own facility, Siegmund has succeeded in creating the hardest, most durable welding surface in the world.

Create a safe and efficient workspace with our top-of-the-line welding benches available at Modern Tools.

The incredibly hard plasma-nitride finish provides dramatically increased resistance to weld splatter, corrosion and scratching, as well as offering the ability to use the table for stainless steel applications. Explore our wide selection of high-quality welding tables in Australia at Modern Tools.

Compare System 28 Tables - Professional 750 or Professional Extreme 8.7 WITH PLASMA NITRATION | |||||||

Professional 750 750 Vickers Premium Steel S35512+N Plasma Nitration | Professional Extreme 8.7 850 Vickers Hardened Tool Steel Plasma Nitration | No Plasma Nitration 220 Vickers Premium Steel S35512+N No Plasma Nitration | |||||

Basic hardness | |||||||

Impact hardness | |||||||

Impact-proof | |||||||

Scratch-proof | |||||||

Protection against weld spatter | |||||||

Corrosion resistance | |||||||

Point load | |||||||

Flatness in its new state | |||||||

Maintenance of the flatness under heavy use | |||||||

Life span | |||||||

Professional 750

Professional 750 welding tables are manufactured of S355J2+N steel and additionally plasma-nitrided and coated. Based on the increased load capacity of the welding table it is especially suited for working with heavy components. By equipping the welding tables with a diagonal grid, the clamping options are nearly doubled. If you are searching for a welding table for sale in Australia, check out our latest offers on top-notch welding tables.

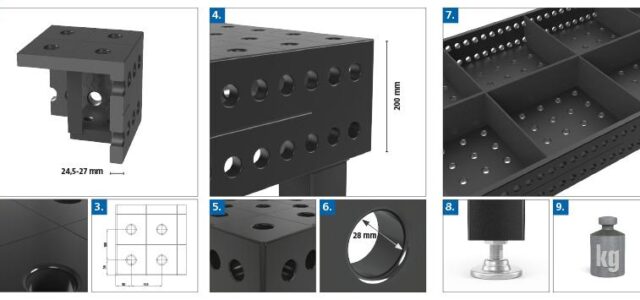

- Material thickness – approx. 24,5 – 27 mm

- Material – premium steel S355J2+N, plasma nitrided and BAR-coated*

- Vickers hardness grade: Surface hardness: approx. 450 – 750, Basic hardness: approx. 165 – 220, * Due to of the lack of material hardness of Professional 750 significantly higher product wear. Optimise your welding efficiency with a sturdy and efficient welding table from Modern Tools.

- Data – Borehole spacing 100 mm, Grid element spacing 100 mm

- Table side panel – 200 mm high additional boreholes enable parallel clamping in 50 mm grid

- Elaborate Radiuses – 3 mm radius of the top table edge reduces damages to Siegmund accessories and customers’ components 6 mm radius on edges reduces the risk of injury

- System borehole –Ø 28,15 mm. Radius R3 for boreholes on the table surface: reduce damages to the table, Siegmund accessories and customer components less adherence of welding spatters on bore edges fewer damages on bore edges while moving heavy components

- Ribbing –spaced apart approx. 500 – 600 mm raised ribbing

- Table Legs – Square pipe 90×90 mm, Base plate Ø 90 mm (made of twisted bulk material), Leg 50 mm vernier adjustment. (Data only for Leg standard equipment)

- Bearing load – Bearing load per leg 2,000 kg.

Maximum recommended static bearing load:

- with 4 legs = 4,000 kg

- with 6 legs = 6,000 kg

- with 8 legs = 8,000 kg

based on even load distribution. (Data only for leg standard equipment) Computationally resulting in substantially higher overall loads. However, the indicated bearing loads were calculated with reserves for safety reasons

Professional Extreme 8.7

Professional Extreme 8.7 welding tables are manufactured of special tool steel and additionally plasma-nitrided and coated. Based on the increased load capacity of the welding table it is especially suited for working with extremely heavy components. By equipping the welding tables with a diagonal grid, the clamping options are nearly doubled.

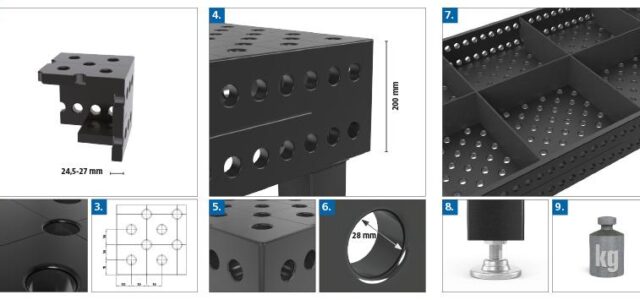

- Material thickness – approx. 24,5 – 27 mm

- Material – Through-hardened tool steel X8.7, plasma nitrided and BAR-coated*

Vickers hardness grade:

- Table top: Surface hardness: approx. 450 – 850, Basic hardness: approx. 280 – 340

- Table side: Surface hardness: approx. 450 – 750, Basic hardness: approx. 165 – 220

* The four side faces are still constructed from our standard, high quality S355J2+N Steel to provide the ideal balance of properties for performance, durability, and cost.

- Data – Borehole spacing 100 mm, Grid element spacing 100 mm

- Table side panel – 200 mm high additional boreholes enable parallel clamping in 50 mm grid

- Elaborate Radiuses – 3 mm radius of top table edge reduces damages to Siegmund accessories and customers components 6 mm radius on edges reduces risk of injury

- System borehole – Ø 28,15 mm Radius R3 for boreholes on the table surface: reduce damages to table, Siegmund accessories and customer components less adherence of welding spatters on bore edges less damages on bore edges while moving heavy components

- Ribbing – spaced apart approx. 500 – 600 mm raised ribbing

- Table Legs – Square pipe 90×90 mm Base plate Ø 90 mm (made of twisted bulk material) Leg 50 mm vernier adjustment(Data only for Leg standard equipment)

- Bearing load – Bearing load per leg 2,000 kg.

Maximum recommended static bearing load:

- with 4 legs = 4,000 kg

- with 6 legs = 6,000 kg

- with 8 legs = 8,000 kg

based on even load distribution. (Data only for leg standard equipment) Computationally resulting in substantially higher overall loads. However, the indicated bearing loads were calculated with reserves for safety reasons.

System 28 - Professional Extreme

- Ultra-durable double hardened and plasma-nitrided tool steel.

- 700 – 850 Vickers surface hardness

- Approximately tenfold lifetime over EN S355J2+N table without nitration

- Hole Diameter:28mm

- Material Thickness:25mm

- Bore and Grid Spacing100mm

- Table Side Face: 200mm

- Table Height: 850mm

System 28 - Professional Extreme Table Size | Table Legs | Weight (approx.) |

1000 x 1000 x 200 | 4 | 416 kg |

1200 x 800 x 200 | 4 | 408 kg |

1200 x 1200 x 200 | 4 | 544 kg |

1500 x 1000 x 200 | 4 | 577 kg |

1500 x 1500 x 200 | 4 | 801 kg |

2000 x 1000 x 200 | 4 | 730 kg |

2000 x 1200 x 200 | 4 | 843 kg |

2000 x 2000 x 200 | 4 | 1299 kg |

2400 x 1200 x 200 | 4 | 986 kg |

3000 x 1500 x 200 | 6 | 1517 kg |

4000 x 2000 x 200 | 8 | 2501 kg |

Note: Weight= table+std.legs+pallet

System 28 - Professional

- Plasma-nitrided tool steel with 480-560 Vickers surface hardness

- Approximately twofold lifetime over EN S355J2+N table without nitration

- Hole Diameter:28mm

- Material Thickness:25mm

- Bore and Grid Spacing100mm

- Table Side Face: 200mm

- Table Height: 850mm

System 28 - Professional Table Size | Table Legs | Weight (approx.) |

1000 x 1000 x 200 | 4 | 416 kg |

1200 x 800 x 200 | 4 | 408 kg |

1200 x 1200 x 200 | 4 | 544 kg |

1500 x 1000 x 200 | 4 | 577 kg |

1500 x 1500 x 200 | 4 | 801 kg |

2000 x 1000 x 200 | 4 | 730 kg |

2000 x 1200 x 200 | 4 | 843 kg |

2000 x 2000 x 200 | 4 | 1299 kg |

2400 x 1200 x 200 | 4 | 986 kg |

3000 x 1500 x 200 | 6 | 1517 kg |

4000 x 2000 x 200 | 8 | 2501 kg |

Note: Weight= table+std.legs+pallet

System 16 - Professional Extreme

- System 16 – Professional Extreme

- Ultra-durable double hardened and plasma-nitrided tool steel.

- Approximately tenfold lifetime over EN S355J2+N table without nitration

- Hole Diameter: 16mm

- Material Thickness: 12mm

- Bore and Grid Spacing: 50mm

- Table Side Face: 200mm

- Table Height: 850mm

Professional Extreme 8.7 Table Size | Table Legs | Weight (approx.) |

1000 x 1000 mm | 4 | 192 kg |

1200 x 800 mm | 4 | 193 kg |

1200 x 1200 mm | 4 | 259 kg |

1500 x 1000 mm | 4 | 279 kg |

1500 x 1500 mm | 4 | 394 kg |

2000 x 1000 mm | 4 | 351 kg |

2000 x 1200 mm | 4 | 412 kg |

2400 x 1200 mm | 6 | 499 kg |

3000 x 1500 mm | 6 | 753 kg |

4000 x 2000 mm | 8 | 1,255 kg |

Note: Weight= table+std.legs+pallet

System 16 - Professional

- Plasma-nitrided tool steel with 480-560 Vickers surface hardness

- Approximately twofold lifetime over EN S355J2+N table without nitration

- Hole Diameter: 16mm

- Material Thickness: 12mm

- Bore and Grid Spacing: 50mm

- Table Side Face: 200mm

- Table Height: 850mm

Professional 750 Table Size | Table Legs | Weight (approx.) |

1200 x 1200 mm | 4 | 261 kg |

1500 x 1000 mm | 4 | 281 kg |

2000 x 1000 mm | 4 | 354 kg |

2400 x 1200 mm | 4 | 503 kg |

3000 x 1500 mm | 6 | 758 kg |

Note: Weight= table+std.legs+pallet

Siegmund Welding Tables - Professional Extreme System 22

System 22 – Professional Extreme

- Through-hardened tool steel X8.7 + Plasma nitration

- Material thickness approx. 17 – 19 mm

- Table side panel made of high quality steel S355J2+N + Plasma nitration

- Borehole Ø 22 mm

- Boreholes on the surface in diagonal grid

- Corners, edges and boreholes rounded

- Height of table side 150 mm

- Borehole spacing of table side 50 mm

- With scaling on the surface

- Construction reinforced with ribbing

- Grid lines allow precise constructions

- Table Height: 850mm

Professional Extreme 8.7 Tool Steel X8.7 Diagonal grid Table Size | Table Legs | Weight (approx.) |

1000 x 1000 mm | 4 | 295 kg |

1200 x 800 mm | 4 | 291 kg |

1200 x 1200 mm | 4 | 387 kg |

1500 x 1000 mm | 4 | 412 kg |

1500 x 1500 mm | 4 | 573 kg |

2000 x 1000 mm | 4 | 519 kg |

2000 x 1200 mm | 4 | 602 kg |

2000 x 2000 mm | 4 | 929 kg |

2400 x 1200 mm | 6 | 725 kg |

3000 x 1500 mm | 6 | 1.073 kg |

4000 x 2000 mm | 8 | 1.807 kg |

Note: Weight= table+std.legs+pallet

Siegmund Welding Tables - Professional Extreme System 22

System 22 – Professional Extreme

- Through-hardened tool steel X8.7 + Plasma nitration

- Material thickness approx. 17 – 19 mm

- Table side panel made of high quality steel S355J2+N + Plasma nitration

- Borehole Ø 22 mm

- Boreholes on the surface in diagonal grid

- Corners, edges and boreholes rounded

- Height of table side 150 mm

- Borehole spacing of table side 50 mm

- With scaling on the surface

- Construction reinforced with ribbing

- Grid lines allow precise constructions

- Table Height: 850mm

Professional Extreme 8.7 Tool Steel X8.7 Diagonal grid Table Size | Table Legs | Weight (approx.) |

1000 x 1000 mm | 4 | 295 kg |

1200 x 800 mm | 4 | 291 kg |

1200 x 1200 mm | 4 | 387 kg |

1500 x 1000 mm | 4 | 412 kg |

1500 x 1500 mm | 4 | 573 kg |

2000 x 1000 mm | 4 | 519 kg |

2000 x 1200 mm | 4 | 602 kg |

2000 x 2000 mm | 4 | 929 kg |

2400 x 1200 mm | 6 | 725 kg |

3000 x 1500 mm | 6 | 1.073 kg |

4000 x 2000 mm | 8 | 1.807 kg |

Note: Weight= table+std.legs+pallet

System 22 – Professional Extreme

- Premium steel S355J2+N + Plasma nitration

- Material thickness approx. 17 – 19 mm

- Borehole Ø 22 mm

- Boreholes on the surface 100×100 mm grid

- Corners, edges and boreholes rounded

- Height of table side 150 mm

- Borehole spacing of table side 50 mm

- With scaling on the surface

- Construction reinforced with ribbing

- Grid lines allow precise constructions

- Table Height: 850mm

Professional 750 Table Size | Table Legs | Weight (approx.) |

1000 x 1000 mm | 4 | 301 kg |

1200 x 1200 mm | 4 | 395 kg |

1500 x 1000 mm | 4 | 420 kg |

1500 x 1500 mm | 4 | 585 kg |

2000 x 1000 mm | 4 | 529 kg |

2400 x 1200 mm | 6 | 740 kg |

3000 x 1500 mm | 6 | 1.097 kg |

Note: Weight= table+std.legs+pallet

Special Offers / Accessories

Product

Download the Siegmund Welding Catalogue

Project Pics

Frequently Asked Questions

Welding tables (also known as a weld table or welding bench) is a work surface that provides welders with the height required to get the job done without unhealthy strain on the body. Not only this, but welding table surfaces are designed to be able to accommodate the range of tools that a welder may use for their job, as well as make regular tasks such as creating corners and edge work as hassle-free as possible. Siegmund welding tables are the cream of the crop, boasting unique plasma nitride surfaces, as well as adjustable legs, and limitless accessories.

Siegmund welding tables are the hardest welding tables in the world. Not only do they boast superior toughness, but the sheer range of accessories they can be used with also makes them the most versatile. Coupled with the plasma nitrating treatment proven to resist weld splatter, corrosion, and scratching, Siegmund welding tables are truly peerless. If you’re looking for Siegmund tables, just look for the brand icon and that will tell you all you need to know.

Plasma nitriding is a thermochemical process that introduces nitrides generated from plasma into the surface chemistry of steel. The nitrides alter this surface chemistry, bestowing several key benefits into the steel. Namely, these benefits include smoother surface finishing, an inability for weld spatter to adhere to the table surface, wear resistance, enhanced longevity, and resistance against corrosion and rust. If that wasn’t impressive enough, Siegmund decided to prove their point by blowing up one of their own tables!

That depends entirely on which one you get. There are six types of Siegmund welding tables. The basic model is made with S355J2+n steel, and has been plasma nitrided. The basic table has a surface hardness of 750 Vickers. Next up from that is the Stainless Steel Welding Table which is NOT plasma nitrided, however it still has a surface hardness of 750 Vickers. Next is the Welding Table Professional 750, the boasting plasma nitride and a surface hardness of 750 Vickers. The Welding Table Professional Extreme 8.7 is also plasma nitride and possesses a surface hardness of 850 Vickers. The 8.8 version of the same table has a surface hardness of 900 Vickers. Finally, the Siegmund Slot Table’s basic hardness is 750 Vickers.

Welding tables provide stability and comfort during welding work. The usually possess holes drilled into them at regular gridded intervals in order to store tools or set up clamps to help the welder hold down their work securely. They also help with regular welding tasks such as squaring and measuring. Siegmund welding tables are the hardest, strongest welding tables in the world. Due to their superior quality, and plasma nitrite practice.