SYSTEM

General Purpose Fabrication

Siegmund recommends the System 22 for fine details to medium-heavy

fabrications. For everyone who cannot decide.

Recommended load up to 3000 kg*

max. 1500 kg per leg basic equipment

Available table series:

Professional 750

Extreme 8.7

Boring Grid:

Diagonal grid

100×100 mm Grid

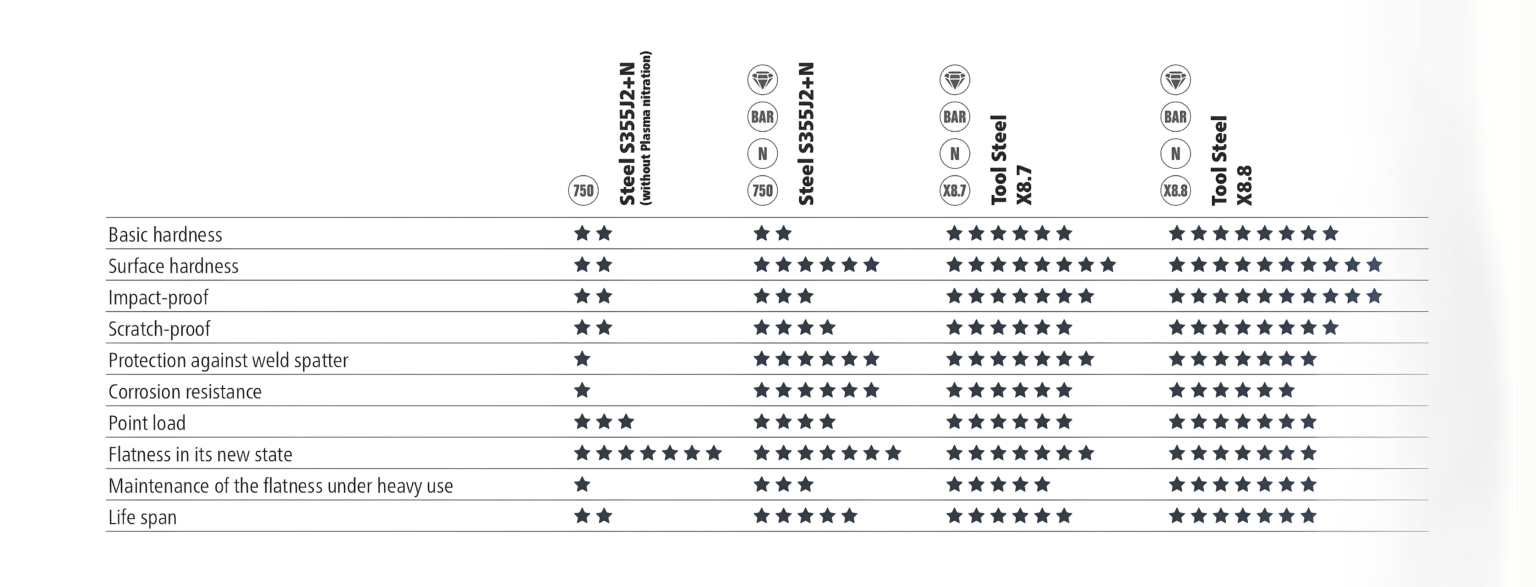

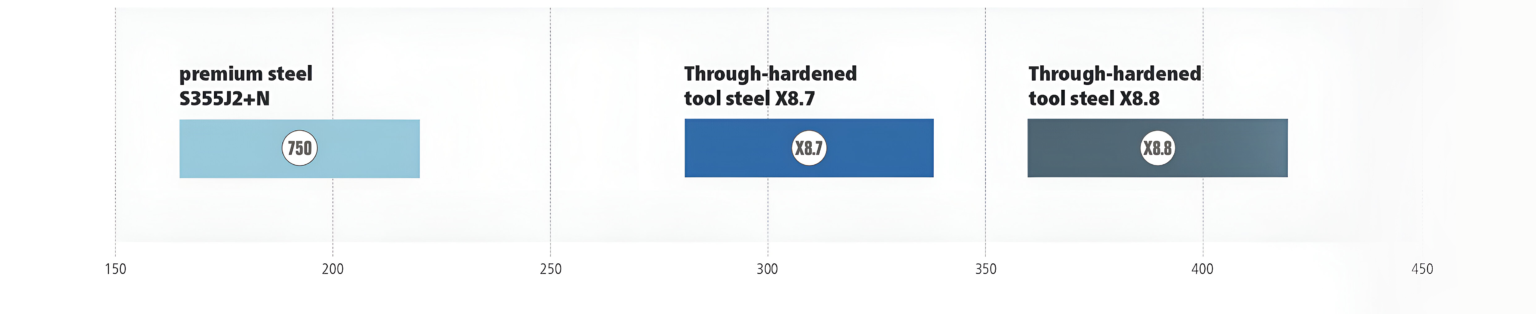

Materials

Basic hardness

Surface hardness

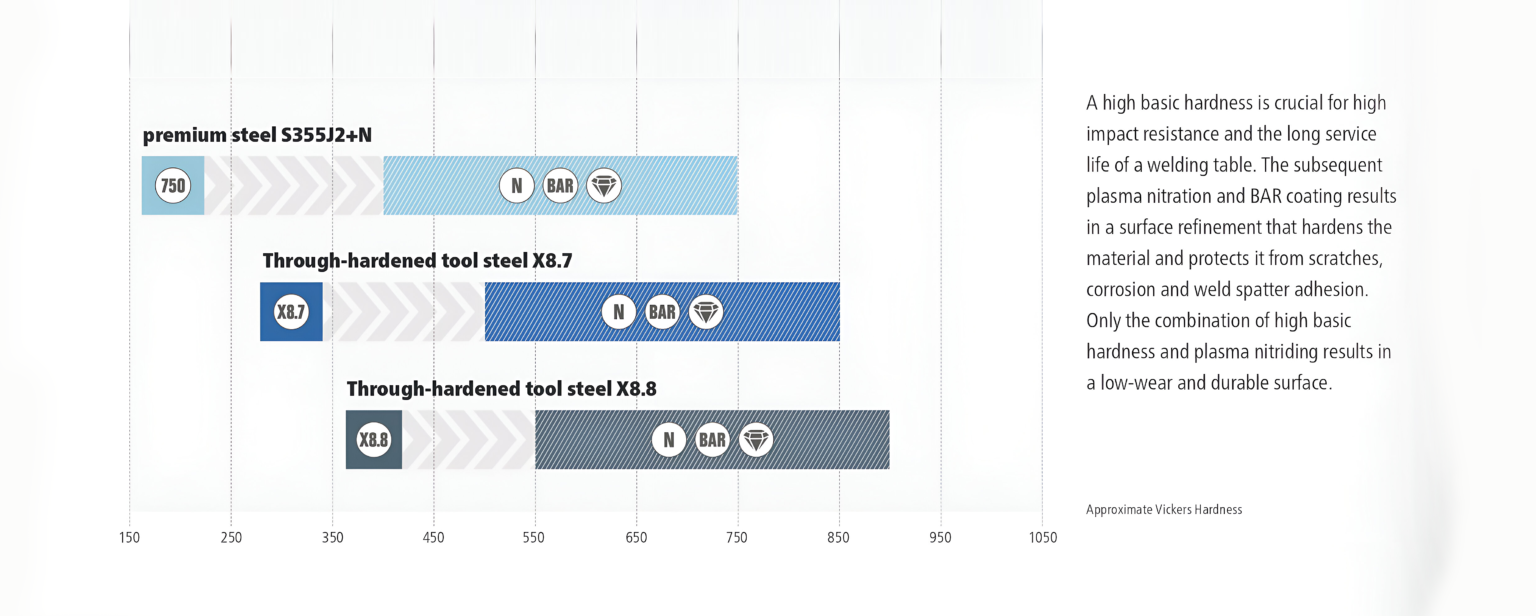

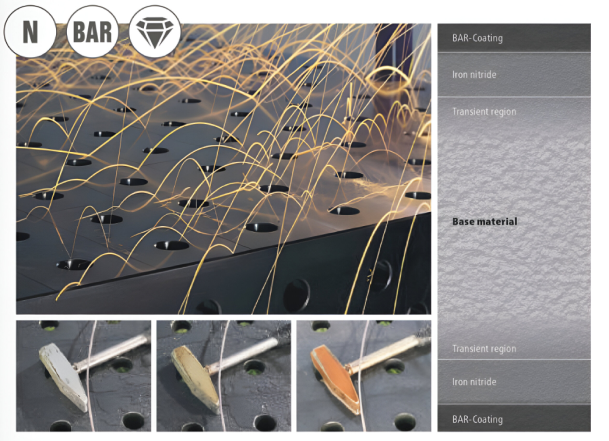

Plasma Nitration

- Proven surface finish Siegmund‘s plasma nitriding is a proven surface treatment for our welding tables.The thermochemical process leads to surfaces that are more wear-free, corrosion-resistant and durable. Welding spatter adheres significantly less to a table with plasma nitriding than to

welding tables without plasma nitriding. As a result, the surface evenness is better preserved even after years. Due to the significant increase in service life and the increased resilience of the welding

Tables by around 20-30%, plasma nitriding is always worthwhile. - Low-wear and durable surfaces

- Scratch resistant

- Corrosion resistant

- Significantly less welding spatter adhesion

CHOOSE YOUR SYSTEM

PROFESSIONAL 750

Material

- Professional 750: Premium steel S355J2+N+Plasma nitration

- Material thickness approx. 17-19mm

Specifications

- Borehole 0 22mm

- Borehole on the surface 100x100mm grid

- Corner, Edges and Boreholes Rounded

- Height of the table side 150mm

- Borehole spacing of table side 50mm

- With scaling on the surface

- Construction Reinforced with ribbing

EXTREME 8.7

Material

- Professional Extreme 8.7 : Through-hardened tool steel X8.7+Plasma nitration

- Material thickness approx. 17-19 mm

- Table side panel made of high quality steel S355J2 + N+Plasma Nitration

Specifications

- Borehole Ø 22 mm

- Boreholes on the surface in diagonal grid

- Corners, edges and boreholes rounded

- Height of table side 150 mm

- Boreholes Spacing of table side 50 mm

- With scaling on the surface

- Construction reinforced with ribbing